currently, the modern consumer market became such that the need to constantly to update the offered range of products. As a consequence, there is a need to reduce the time of their production. Technologically.

the Use of universal machines has become possible due to breakthroughs in the field of production of high strength tool steel, which was capable of withstanding very high loads and industrial microprocessors.

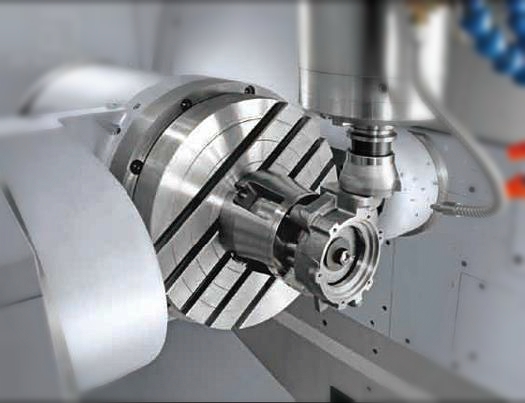

industry examples of such machines are lathes and machining centres. Their peculiarity is that they can contain multiple spindles and turret, as well as shopping for tools.

the What is a lathe center

This equipment is designed to perform turning operations on metal. In particular, for processing workpieces, representing the body of rotation. This axis, flanges, bearings, valves, etc.

In essence, due to the fact that it is equipped with a conveyor for transportation of finished products, technologically this unit is similar to the reduced copy of your conveyor line.

This center can perform the following types of turning operations

— treatment of outer and inner cylindrical surfaces;

— treatment of outer and inner conical surfaces;

— machining face and square shoulder milling;

— making grooves cut billets;

— cutting internal and external threads;

— drilling holes;

— treatment of shaped surfaces;

— the application of a serration.

As a rule, the management of such a centre is available in semi-automatic and automatic modes, as well as through machine interface, which is known as CNC. Here there is an option when implemented advanced mechanical control. Here it acts as a duplicate. This is especially true in case of breakage of the workpiece or the tool.

currently most of the centres are produced with CNC. Therefore, it is advisable to consider such kind of machine.

Machining centre consists of a body frame, the working chamber of the power unit with head and spindle, control units, conveyor, cooling systems, ventilation, removal of shavings, shelves for storage of tools, and also shop for tool change in automatic mode.

based on the design of the equipment remains solid frame. It can be made exactly horizontal or at an angle to the base. In the second case, the angle of inclination can reach up to 70 degrees. This is done to facilitate automatic loading and unloading of parts, a more uniform distribution of vibration over the whole body. The result is a higher precision machining and easy chip removal from the treatment zone.

In the working chamber is made by machining of workpieces. For safety it has doors that incorporate impact-resistant glass. Here are the spindles and rails, attached to the frame. The first is that they are capable of operating at very high speeds. In practice, the speed of rotation may be different depending on the size of the workpiece.

it is Clear that the larger the diameter, the required lower speed to ensure high-quality machining without tool breakage. Tend to be some models of machining centres designed for machining of large diameter and the other small.

as the power drive is a powerful motor, which is powered by three-phase network. Typically, each spindle has its own drive.

Spindle are based on the angular contact bearings to withstand heavy loads in both radial and axial directions. This has a positive effect on the service life of the machine and the quality of the final product.

Machining center has a turret for changing tools in automatic mode. The number of positions may be 8 or 12. The tools themselves are stored in stores, which can move in the working area. The condition of tools is monitored with the help of special sensors, as well as technical personnel.

To increase the reliability of the tool is a hydraulic three-jaw Chuck.

the control Unit of the CNC machining center consists of a main microprocessor, control microcontroller, electric drives, which are responsible for the movement of the workpiece, different sensors. Software control allows you to operate the machine in a fully automatic mode.

For order and cleanliness in the working area is the responsibility of the ventilation system and removal of chips. There is cooling of the cutting area. It is organized with the help of tubes, from which is fed the emulsified liquid. As a rule, each spindle is supplied as a separate tube. Thanks to them, it is possible to produce enough high-quality processing of the workpiece.

This equipment is used in the following fields

— mechanical engineering;

— electrical and instrument-making industry;

automotive;

— Avia-space industry;

— the military-industrial complex.

it is Worth noting that they are used for shafts of all types, fittings, mould, dies in almost all industries.

At such centers is machining of workpieces made of materials such as steel of different grades, non-ferrous metals (aluminium, copper and their derivatives).

the Kinds of turning machining centres

By way of control, such equipment is divided into the following types:

— semi-automated;

automatic;

— CNC.

the Lathes machining centers with semi-automatic control

semi-automatic management of technological operation of processing one workpiece in one work cycle are automatically performed. However, there is a need for operator intervention for tool change, loading and unloading of the workpiece. Therefore, they are not suitable for use in serial production.

the Lathes machining centers with automatic control

In this case, the machining is performed in automatic mode within one cycle, but the entire workflow. Usually part of conveyor lines for the production of products.

the Lathes machining centers NC

These have been discussed above. Therefore, it is worth noting that this kind of machinery is best suited for the title of universal aggregates. Their capabilities are essentially limited to the control program, the number of positions turret, and the degrees of freedom of movement of the guides. In fact, some models can replace the whole technological cycle of production of the product.

the Advantage of this equipment is that it is able to perform the greatest number of technological operations in a single pass. It allows to reduce time of manufacture of the final product, and reduce its cost. The enclosed design provides security during processing. The use of such centres provides the opportunity to reduce production area.